Steel Manufacture

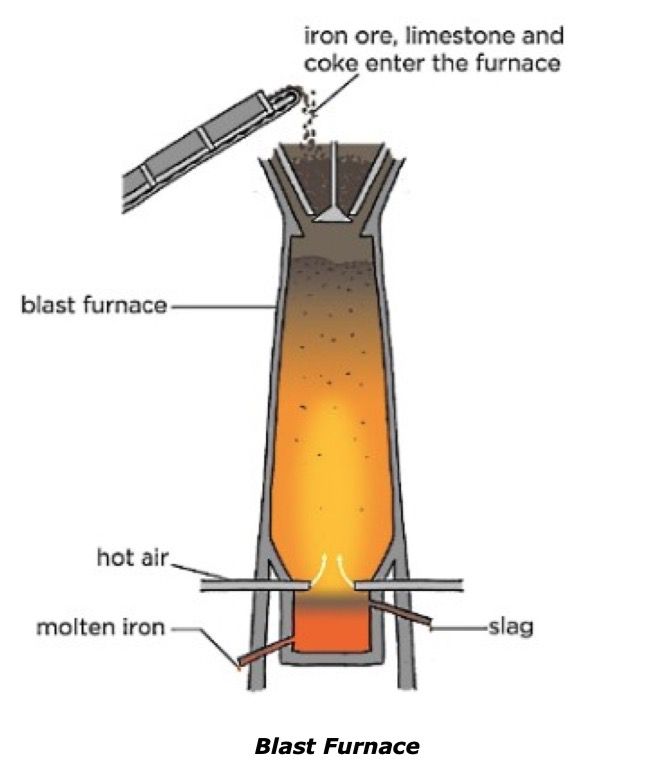

Blast Furnace

When iron ore has been concentrated to a usable value, it is ‘smelted’ in a blast furnace to give a pure metal which can be mixed with other elements to give the required properties.

The iron ore is fed into the blast furnace along with coke and limestone which are heated to above the iron’s melting point, this then falls to the bottom of the furnace along with the slag for tapping off when required. The iron at this stage is known as pig iron containing up to 4% carbon and other impurities, including unwanted material making it brittle and requiring further processing.

In the steel making process, materials are added which form ‘compounds’ with the impurities which are thus removed from the steel as gas or slag. The output from this refining is now called steel and may be cast into an ‘ingot’ for later processing or into a continuous casting (concast) machine.

Ingot casting tends to be used for short runs or special materials, whereas continuous casting allows continuous production of a standard material specification and a range of simple cross sectional shapes.